Design Features of TA-Series Tap Arm System

This is a serious machine with a simple, clean design offering a cost effective solution for years of thread tapping in a job shop or O.E.M. part production.

This is a serious machine with a simple, clean design offering a cost effective solution for years of thread tapping in a job shop or O.E.M. part production.

ETA Tap Arms are warrantied against excessive wear and part breakage under normal industrial use for a period of 5 years.

This 5 year warranty includes all bearings, bushings, shafts, and float cylinder for an unlimited number of tapped holes!

Many customers use our arms all day, every day for years. 2015 marked our 5th year in business and essentially no warranty claims.

Note; The Sioux Tap Motor is covered for 1 year by Sioux Tools, Inc through ETA. Please see our warranty for full details.

ETA Tap Arms are warrantied against excessive wear and part breakage under normal industrial use for a period of 5 years.

This 5 year warranty includes all bearings, bushings, shafts, and float cylinder for an unlimited number of tapped holes!

Many customers use our arms all day, every day for years. 2015 marked our 5th year in business and essentially no warranty claims.

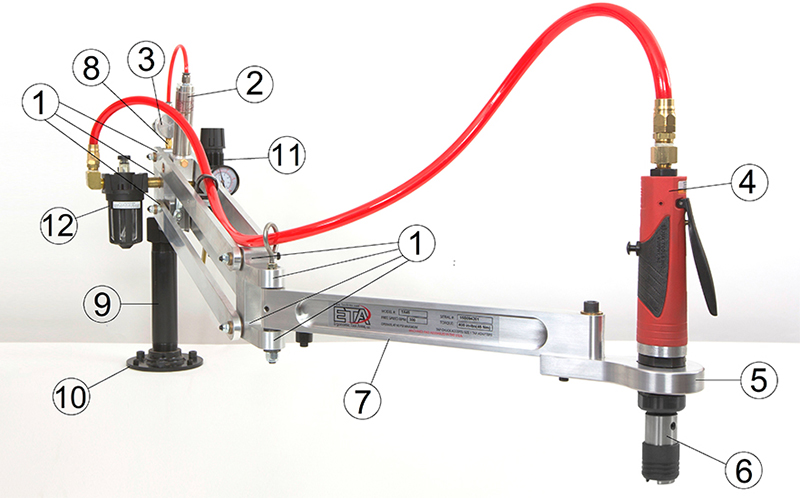

Note; The Sioux Tap Motor is covered for 1 year by Sioux Tools, Inc through ETA. Please see our warranty for full details.- Precision Machined Pivot Points. Permanently lubricated bearings are hand fit to their ground shafts within 0.0003 inches (.007mm) or better and pivot on Roller Thrust Bearings for the most rigidity and smoothest movement possible. WARRANTIED 5 YEARS AGAINST EXCESSIVE WEAR. Machined, ground and assembled in Pennsylvania, USA.

- ETA Air Cylinder Floatation will Outlast and Outperform sealed gas springs, coil springs and spring loaded cable balancers many, many times over. And our air cylinder performance will not degrade gradually the way sealed gas springs do. With clean, dry compressed air, rated life-cycle of our cylinders is a minimum of 50,000,000 (50 million) holes! Cylinder is Mounted Upright so that float is consistent as you raise and lower the Tap Arm without the "toggle" feel experienced on sealed gas springs and other's air cylinders mounted on a bias inside the arm. Cylinder is made for ETA in the USA.

- Float Regulator is Easily Adjusted in seconds with the twist of the knob. Set it once and forget it. No further adjustment or maintenance for many millions of holes. Reg. is made for ETA in the USA.

1.0 HP Industrial Tap Motor - Choose from 4 different RPM / Torque Ranges. See Model Selection. Sioux's new air motor is designed for increased life span and more power. Insulated comfort grip houses a smaller diameter but longer motor to deliver the most torque without compromising ergonomics. Start lever & reverse button are well positioned for repetitive tapping cycles.1.0 HP gives ample power for Size 1 taps. Sioux Warrants the motor 1 year against defects in material or workmanship through ETA. We also offer post-warranty motor repair and spare motors. Made in North Carolina, USA.

1.0 HP Industrial Tap Motor - Choose from 4 different RPM / Torque Ranges. See Model Selection. Sioux's new air motor is designed for increased life span and more power. Insulated comfort grip houses a smaller diameter but longer motor to deliver the most torque without compromising ergonomics. Start lever & reverse button are well positioned for repetitive tapping cycles.1.0 HP gives ample power for Size 1 taps. Sioux Warrants the motor 1 year against defects in material or workmanship through ETA. We also offer post-warranty motor repair and spare motors. Made in North Carolina, USA.- ETA Tool Holder and hose swivel allows the Tap Motor Lever to be repositioned to operators preference by loosening 1 cap screw. For horizontal tapping the vertical holder shown here can be easily switched with model HTMH (Horizontal Tap Motor Holder) when required.

Size 1 Quick Change Tap Chuck, no tools needed to change taps. Made in Germany

Size 1 Quick Change Tap Chuck, no tools needed to change taps. Made in Germany- Operator has uncluttered view of work area. All moving parts and pneumatics are in the back of the arm so there is a more open view of the part being tapped. Forearm (front half of arm) is only 1 inch (25.4mm) wide.

- Check Valve prevents arm from falling rapidly if there is a sudden loss of air supply.

- Mounting Post is 1-1/4 npt Iron Pipe which makes it easy to accommodate different mounting locations and positions and still have the arm in the correct work zone. See Our Mounting System below and Mounting Ideas for more info. TA-Series Base Assembly has an 8" long pipe nipple standard. For floor or overhead mounts from long distances we offer our B250 Heavy Duty Base.

- Welded Steel Mounting Base with 3 leveling screws and 3 mounting holes for 3/8" (M8) bolts. Post Threads are 1-1/4 npt. Forged, cut & welded in Pennsylvania, USA.

- 5 Micron Filter / Pressure Regulator unit with Gage, 3/8 npt inlet. Made in USA.

- Lubricator Unit for use only with Air Tool Oil. Made in USA.

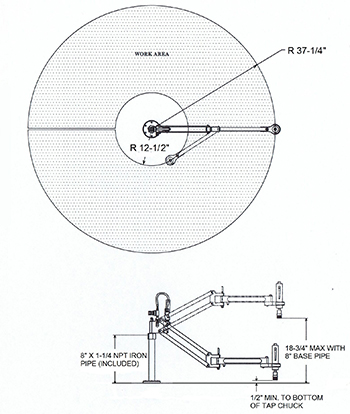

TA-Series Coverage Area (Reach)

Our Mounting System

ETA Tap Arm Systems use standard black iron or galvanized 1¼” NPT steel pipe for the mounting base post. Tap arms are shipped with a 8” pipe nipple assembled to our heavy steel base plate and powder-coated black. Using standard pipe provides a strong mount that is easily adaptable to your circumstances.

If your TA-Series arm is going to be mounted on a flat bench top then a tap placed into a TLA holder will reach low enough to tap a hole in a part flat of the bench surface. For changing the vertical reach in relation to the mounting height 1¼ NPT iron pipe nipples are available at home centers and hardware stores.

ETA Base should be bolted to a plate steel or heavy reinforced bench top for best results. Use [3] grade 5 or better 3/8” or M8 bolts. Leveling screws are provided in our mounting base to assist in the leveling the tap arm.

See Mounting Ideas for more information.

ETA Tap Arm Systems use standard black iron or galvanized 1¼” NPT steel pipe for the mounting base post. Tap arms are shipped with a 8” pipe nipple assembled to our heavy steel base plate and powder-coated black. Using standard pipe provides a strong mount that is easily adaptable to your circumstances.

If your TA-Series arm is going to be mounted on a flat bench top then a tap placed into a TLA holder will reach low enough to tap a hole in a part flat of the bench surface. For changing the vertical reach in relation to the mounting height 1¼ NPT iron pipe nipples are available at home centers and hardware stores.

ETA Base should be bolted to a plate steel or heavy reinforced bench top for best results. Use [3] grade 5 or better 3/8” or M8 bolts. Leveling screws are provided in our mounting base to assist in the leveling the tap arm.

See Mounting Ideas for more information.

About Tap Adapters

Tap Adapters are the link between your tap and the Bilz Quick Change Tap Chuck on our tap system. Tap Adapters are sized specifically for each shank and square size. Thread pitch or number of threads per inch does not affect adapter size. For example; a 1/4-20 and a 1/4-28 tap have the same shank and square dimensions. Further, some shank sizes are shared by different thread sizes, particularly the smaller, numbered thread sizes. See Tap Adapters for details. Typically metric taps made in the USA share shank & square dimensions with their closest inch size. Metric taps made outside the USA use DIN Standards and so have different square sizes (see sections 4 & 5 of Tap Adapters for DIN Standard Metric Tap Adapters).

ETA TA-Series Tapping Arm Systems have a Size 1 Bilz Tap Chuck. Standard tap range for Size 1 adapters is Screw Size 0 through 9/16 or M14 Threads. We also have Extended Range Holders for larger threads in softer materials like plastic and aluminum. You can also use other brands of Size 1 tap adapters in our Bilz Tap Chuck such as T.M. Smith, Collis, Universal, Lyndex, Accupro, Centaur, Emuge, Erickson, Parlec, Flexarm and others.

NO TOOLS REQUIRED

To install a tap you simply push the shank into the adapter until it is fully seated and will not pull out. To remove a tap push down on the small collar surrounding the tap with your finger and pull on the tap with your other hand. Once a tap is in the Adapter insert the Adapter into the Tap Chuck on the Tap Motor lining up the drive tabs on the adapter with the notches on the Tap Chuck. Once the adapter is seated the collar will automatically snap forward locking the adapter into the Tap Chuck. To remove the adapter pull back on the chuck's outer collar, releasing the adapter.

We recommend using Torque Limiting Adapters with our tap arms (ETA Adapter Models that start with TLA). These adapters have a built in clutch, set at the Bilz factory, to slip at approximately 60% of the breaking strength of the course tap of that particular size. Typically the factory clutch setting is just right, but these clutch settings are easily changed when needed. See Adjusting Torque Limiting Adapters.

TLA Adapters enable an operator to run a tap to the bottom of a blind hole, when necessary, without fear of breaking the tap. TLA adapters used on ETA Tap Arms also work nicely with cold form taps (roll threads).

Some people prefer to use direct drive adapters (ETA Adapter Models that start with TPD).These adapters do not have a clutch to prevent tap breakage. In some cases this is a not a problem (typically larger taps for through holes) but for best results we recommend using TLA adapters exclusively with our tapping arms. Torque Limiting Adapters are certainly essential for all blind holes and smaller thread sizes.

top of the page

top of the page

Tapping Capacity.

It is not our intension in this writing to cover all possible thread cutting circumstances, but rather to provide general guidelines.

Maximum tap sizes of TA-Series Tap Arms in our Model Selection Charts are based on actual shop tests and conservatively stated. However, they are dependent on a number of factors beyond our control, including air supply volume, hole size, hole depth, tap configuration , tap dullness, thread cutting lubrication, and tap motor lubrication. Tests were done at ETA using standard HSS straight flute taps or HSS spiral point - straight flute taps. If your application requires thread sizes at or near the limits on our model chart, as a free service, we can run samples with an ETA Tap Arm at our facility using your tap and your parts. Consult your ETA distributor or contact ETA directly to make arrangements for a test.

Why use an ETA Tap Arm System?

Is tapping holes a dreaded task for your company or are you suddenly faced with a new product with tapped holes and you are not sure how you are going to make it happen efficiently and consistently?

Cutting threads by human power or unguided handheld power tool is difficult and the resulting threads are often suspect. Keeping the tool straight and steady by hand is a big challenge. Tap breakage often occurs under these circumstances. With thin materials, taps might not break but threads are often cut out of square to the face of the material.

Hand Tapping Presses are inexpensive and will keep the tap straight but have limited opening for the combined height of your part and the length of the tap. And you have to move and line up the part for each hole. And then you must turn the handle by hand which could be an ergonomic issue if you have more than a few holes to tap. And Tapping Press adapters do not have a torque limiting clutch in them.

Tapping on a CNC milling machine is very effective….. A great solution… but it’s expensive, especially if you don’t already have a mill that has time available on it. If you have parts with holes that just need threads then generally parts have to be relocated to the milling machine and fixtured. And a more experienced employee must program and run a CNC machine tool.

A drill press or manual mill with a tapping attachment will tap nicely, but you have to relocate and reclamp the part for each hole. This is very time consuming.

ETA Tap Arms solve all of the problems above for a modest cost. Here’s why;

It is not our intension in this writing to cover all possible thread cutting circumstances, but rather to provide general guidelines.

Maximum tap sizes of TA-Series Tap Arms in our Model Selection Charts are based on actual shop tests and conservatively stated. However, they are dependent on a number of factors beyond our control, including air supply volume, hole size, hole depth, tap configuration , tap dullness, thread cutting lubrication, and tap motor lubrication. Tests were done at ETA using standard HSS straight flute taps or HSS spiral point - straight flute taps. If your application requires thread sizes at or near the limits on our model chart, as a free service, we can run samples with an ETA Tap Arm at our facility using your tap and your parts. Consult your ETA distributor or contact ETA directly to make arrangements for a test.

Why use an ETA Tap Arm System?

Is tapping holes a dreaded task for your company or are you suddenly faced with a new product with tapped holes and you are not sure how you are going to make it happen efficiently and consistently?

Cutting threads by human power or unguided handheld power tool is difficult and the resulting threads are often suspect. Keeping the tool straight and steady by hand is a big challenge. Tap breakage often occurs under these circumstances. With thin materials, taps might not break but threads are often cut out of square to the face of the material.

Hand Tapping Presses are inexpensive and will keep the tap straight but have limited opening for the combined height of your part and the length of the tap. And you have to move and line up the part for each hole. And then you must turn the handle by hand which could be an ergonomic issue if you have more than a few holes to tap. And Tapping Press adapters do not have a torque limiting clutch in them.

Tapping on a CNC milling machine is very effective….. A great solution… but it’s expensive, especially if you don’t already have a mill that has time available on it. If you have parts with holes that just need threads then generally parts have to be relocated to the milling machine and fixtured. And a more experienced employee must program and run a CNC machine tool.

A drill press or manual mill with a tapping attachment will tap nicely, but you have to relocate and reclamp the part for each hole. This is very time consuming.

ETA Tap Arms solve all of the problems above for a modest cost. Here’s why;

- Arm floats almost weightless and moves effortlessly from hole to hole.

- Arm holds the tap motor firmly in alignment with your clamped or fixtured part.

- Arm eliminates all torque reaction created by the thread cutting or thread forming process.

- Arm will not bend, twist or sag under motor’s torsional load, so alignment is assured on every hole provided your components are properly positioned and secured.

- Since the arm floats in X, Y & Z axis the tap will always follow the hole as long as it is drilled straight and fixtured straight. It will not cut threads off center of the hole.

- Tap Adapters snap quickly in and out of Bilz Tap Chuck without tools, making it possible to change out dull taps or switch tap sizes in a few seconds. Operator can efficiently cut multiple thread sizes on the same part, in the same operation.

- Torque Limiting Tap Adapters (TLA-xxx) greatly reduce the chances of breaking taps. As taps get dull, the torque required to cut threads increases. Without a TLA ultimately, if use of a dull tap continues too long, the cutting torque exceeds the torsional strength of the tap and the tap breaks. Likewise, tapping shallow blind holes typically results in damaged threads and broken taps if the tap hits the bottom of the hole or chips accumulate and pack into the hole during the threading process. Torque Limiting Adapters (TLA) slip once a maximum torque is exceeded, as when the tap is driven to the bottom of a blind hole or a dull or unlubricated tap is used in a through hole, etc. The adapters are set at the Bilz factory for 60% of breaking torque for tap size, but this clutch can be adjusted for more or less torque as necessary for your operation. Note; Spiral flute taps will pull chips up and out of the hole but they break easier and at lower torque than straight flute taps. Straight flute taps and spiral point taps typically push the chips into the bottom of the hole. Thread forming taps do not create chips but require a different hole size and additional torque.

- Air motors like the models used on the TA-Series are ideally suited for production tapping because they can be switched into reverse while still going forward without consequence to the air motor. While advances in electronics make electric motors less susceptible to issues caused by rapid reversing, costs associated with doing so can be higher than using a simple air motor like our Sioux Signature Series.